Yamaha Viper Updates

Before the production Vipers hit the snow, Yamaha already made improvements

A couple of decades back, we were at a photo test ride and photo session in the western mountains gathering images and impressions of a brand new Arctic Cat performance snowmobile. We were satisfied in its ride and potential, but Arctic Cat engineers were not. So not satisfied that the top engineers, including the VP of engineering, came in from the Thief River Falls headquarters to check out the problems, hunt for solutions and move the program ahead so as not to lose manufacturing time.

As we recall, that particular model had its pre-production issues solved and the full production versions came to be one of Arctic Cat fans’ favored sleds. This was not the first time we’d seen such changes.

Consumers win as Yamaha made a number of updates to its new 2014 Viper since we tested it back in March. Some changes are cosmetic while others improve reliability and durability – both Yamaha hallmarks!

Consumers win as Yamaha made a number of updates to its new 2014 Viper since we tested it back in March. Some changes are cosmetic while others improve reliability and durability – both Yamaha hallmarks!Frequently, when we ride pre-production models at the annual photo and test ride sessions in March; they have weeks left to get fine tuned and last minute spec updates. Despite the thousands of miles models are test ridden by factory specialists, ways to make a sled better arise – and usually at the last minute! Sometimes the changes happen because suppliers get specified parts to the manufacturer late. Sometimes a part may be flawed and the snowmobile manufacturer makes the supplier get it right or there may be a newer, better part coming on stream that is worth waiting to get. And, of course, some times great ideas don’t work out as well as hoped and a fix is necessary.

2014 Yamaha Viper vs. 2002 Yamaha SX Viper

Whatever the reason, over the years we have seen manufacturers work very hard on their products to get them right for production. In fact, this seemingly never-ending effort to make their products better is one thing that we admire about the snowmobile manufacturers. The engineering staffs care about the end product that we ride. That’s not to say it can’t always be better, because the snowmobile engineers that we know are constantly striving to make the best sled they can.

Select Viper models feature high performance Fox FLOAT 3 “air” shocks, complete with a Kashima coated piston to reduce friction and “Samurai” sealing system for extended durability.

Select Viper models feature high performance Fox FLOAT 3 “air” shocks, complete with a Kashima coated piston to reduce friction and “Samurai” sealing system for extended durability.For example, you might think that Yamaha’s all-new 2014 SR Viper would be perfect except for a few tuning issues they might need to fine-tune the Yamaha one-liter four-stroke triple to Arctic Cat’s Procross chassis. After all, other than the bolting the Yamaha triple into place and working out performance criteria, what’s left?

Actually, it seems that after we test rode the sleds last March, Yamaha and Arctic Cat engineering crews worked into June to find a number of ways to make the Viper better for production. As we looked at the list of updates, we saw a list of things that will make the Viper more durable, more reliable and trouble-free. The list of improvements included some items that probably could have been left out and wouldn’t be noticed or missed. But that isn’t the way Yamaha does things – nor the other sled makers based on our past experiences.

What did Yamaha do to make the 2014 Viper a better production sled than pre-production one?

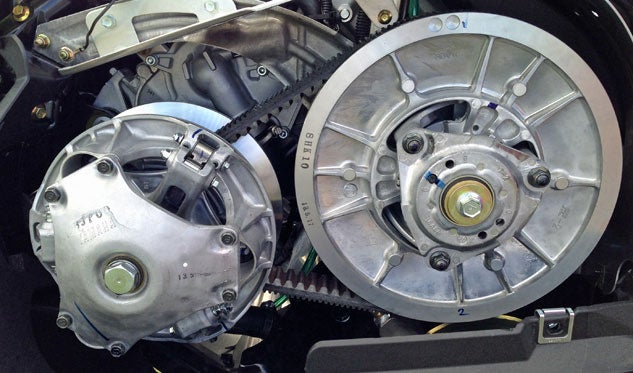

There’s a new drive belt that more precisely matches the sled’s driver to driven pulley center-to-center distance. And the good news? The belt retails for about a hundred bucks!

The new chassis and engine placement on the Viper required changing to a belt that best matches the new needs of the clutches, plus the new belt should retail for US$100.

The new chassis and engine placement on the Viper required changing to a belt that best matches the new needs of the clutches, plus the new belt should retail for US$100.As well, Yamaha upgraded the drive chain, making it the same as the 13-link Borg Warner product used on its high-powered Apex four-cylinder engine. In addition, the gears should last longer as they are now billet cut instead of die-cast. The chain tensioner features manual adjustability for longer chain life, but does require a 500-mile service interval.

The higher revving and more powerful Yamaha triple invited upgrading the drive chain, adding a manual tensioning system and specifying billet cut gears.

The higher revving and more powerful Yamaha triple invited upgrading the drive chain, adding a manual tensioning system and specifying billet cut gears.Since the Yamaha triple cylinder provides greater revs and overall horsepower, a decision was made to go with a final track drive that features an introvert-toothed drive sprocket along with an extrovert cog grip that helps reduce track ratcheting. Yamaha engineers feel that this drive sprocket set up will enhance chain drive life as well.

The drive sprocket features both teeth and extrovert cogs to minimize track ratcheting and maintain maximum power to the snow.

The drive sprocket features both teeth and extrovert cogs to minimize track ratcheting and maintain maximum power to the snow.Since the three-cylinder Yamaha four-stroke is actually a bit wider than the previous Suzuki twin, Yamaha opted on the side of durability by adding an aluminum cross brace at the engine mount for extra rigidity and overall strength. The addition of standard aluminum tunnel protectors strengthens the tunnel and minimizes the effects of the track slapping the tunnel under the seat.

While we have expressed our enthusiasm for the Viper seating position, Yamaha decided to improve it by using a slightly softer seat foam with a thicker seat pan. Ride position should be what we praised, but we expect improved seating comfort. To better secure the seat for travel over rough terrain at the higher speeds the sled will invite, engineers devised a new “bolt latch” system at the rear of the seat.

Yamaha added a bolt latch system to way to secure the seat, which also features new softer foam and a thicker seat pan.

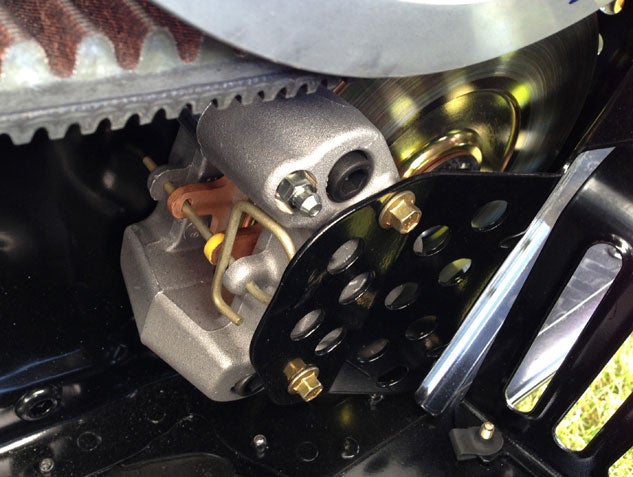

Yamaha added a bolt latch system to way to secure the seat, which also features new softer foam and a thicker seat pan.From a sled performance standpoint, the 2014 Viper series receives updates directly related to racing experiences. For one, a change to the hydraulic brake system now features a “racing-style,” more rigid outer brace. Up front on select Viper models you’ll find race-proven high performance Fox FLOAT 3 “air” shocks, complete with a Kashima coated piston to reduce friction and “Samurai” sealing system for extended durability.

Based on positive experience in racing applications, engineers decided to go with a more rugged and reliable outer brace for the hydraulic brake.

Based on positive experience in racing applications, engineers decided to go with a more rugged and reliable outer brace for the hydraulic brake.Pretty much strictly for looks, the Viper front-mount radiator will be black so it won’t be readily seen through the sled’s hood louvers.

The Yamaha and Arctic Cat Collaboration

Use of a “blacked out” radiator is mostly for cosmetics, but other upgrades like tunnel protectors add rigidity to the chassis.

Use of a “blacked out” radiator is mostly for cosmetics, but other upgrades like tunnel protectors add rigidity to the chassis.Over the years these are the type of “last minute” changes frequently made during the weeks between our test rides in the spring and the time that the sleds actually roll off the assembly line. In general, it’s rare that wholesale updates get made on new introductory models. After all, the Arctic Cat chassis used by the Viper is in its third production cycle so it should be pretty well figured out by now. However, melding the two brands together did require some tweaking, even some of the “last minute” kind.

The end result is a final production unit that gives Viper owners exactly the reliability, durability and four-stroke performance that they expect from a Yamaha branded snowmobile.

Your Privacy Choices

Your Privacy Choices